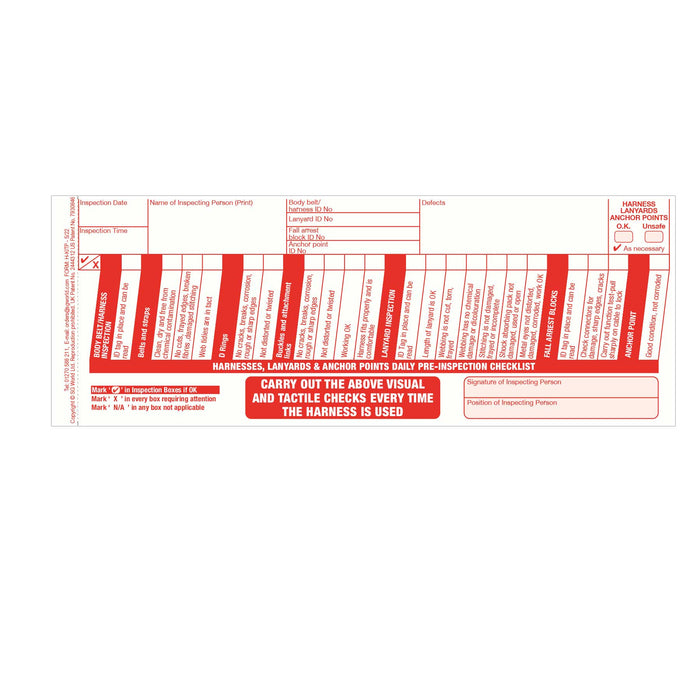

Harness Pre-Use Visual Inspection Checklist (Pad of 30)

A safety harness equipment inspection checklist is used by workers at heights to ensure that a harness is in good condition before use and reduce the risk of falling. The checklist is designed to help you comply with your duty of care under HSE guidance, PUWER and Personal Protective Equipment at Work Regulations. The duplicate checklist design creates two signed copies of each inspection and incorporates a PASS/FAIL notice. Each pad has 30 checklists and is used in tandem with a hi-vis display wallet

Dimensions: 84mm (h) x 229mm (w)

Order your free sample

Order our free sample pack and take one for a test drive

How to use

Before every shift, the harness wearer can simply work down the inspection checklist, checking the safety of each component in turn. Once the pre-use inspection is complete, assuming safety has been established, the green PASS inspection certificate can be placed inside a safety status indicator ensuring that everyone can clearly see that the harness is safe for use. Failing harnesses can be similarly identified by a red FAIL certificate and reported for maintenance or destroyed. The duplicate copy of the certificate remains inside the inspection pad and can be used as evidence of inspections should you ever need to produce this for the HSE or other official parties.

If you've got any other questions you can check out our How To Page for more information.

FAQs

What often should a safety harness by inspected?

As with all PPE, harnesses must be examined at least 12 monthly and should also be subject to Pre-Use Checks, Detailed Periodic Inspections and Interim Inspections.

For frequently used equipment used in demanding conditions such as scaffolding, the NASC recommend a formally recorded detailed inspection is undertaken at least every 3 months.

What is a harness pre-use safety check?

The HSE recommends that pre-use checks should be tactile and visual. The whole lanyard should be subject to the check, by passing it slowly through the hands (eg to detect small cuts of 1 mm in the edges, softening or hardening of fibres, ingress of contaminants). A visual check should be undertaken in good light and will normally take a few minutes

How do I carry out a harness pre-use check?

Inspecting your fall arrest harness should be an essential part of your routine. Break up the inspection into these steps.

1. Check the label

2. Hardware check including D ring, back plate, fasteners, adjusters and connectors

3. Fabric check the webbing

Remember cleaning and storing a harness will help keep it in safe working condition

Check out our full range of pre-use safety inspection articles and guides.

Want to customise?

Looks good but need something personalised for you and your workplace? Check out our customisation options.

SG World have in-house expertise in design, print and software development, so if you’re looking for something with your personal branding, a quick format tweak or a complete re-design, we have the experience and resources in place to quickly transform an idea into a practical solution. Complete our Contact Us form here and we’ll be in touch to discuss your ideas.