Compactor Pre-Use Visual Inspection Checklist (pad of 30)

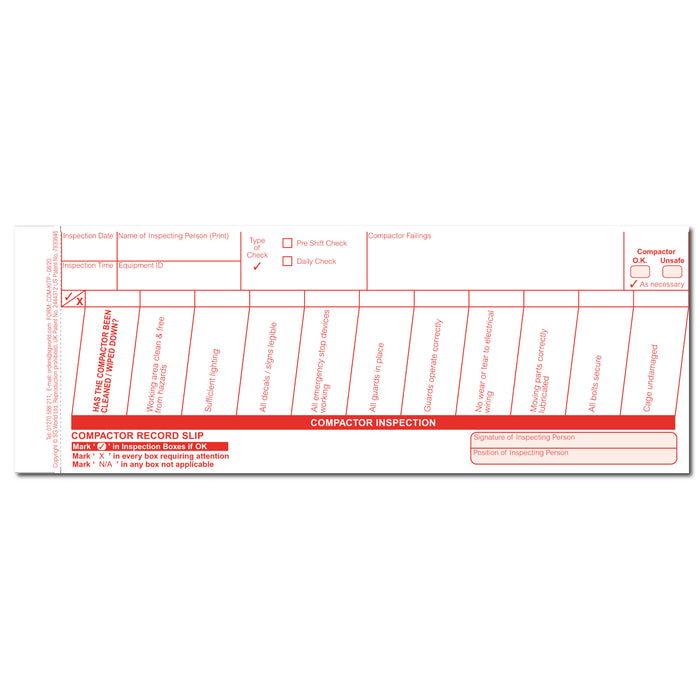

Compactors compress recovered material or waste into a container for eventual recycling or disposal. Machines typically include a feed inlet, compaction chamber and outlet to a skip/container. The compactor inspection pad helps you perform their pre-use or daily safety inspections.

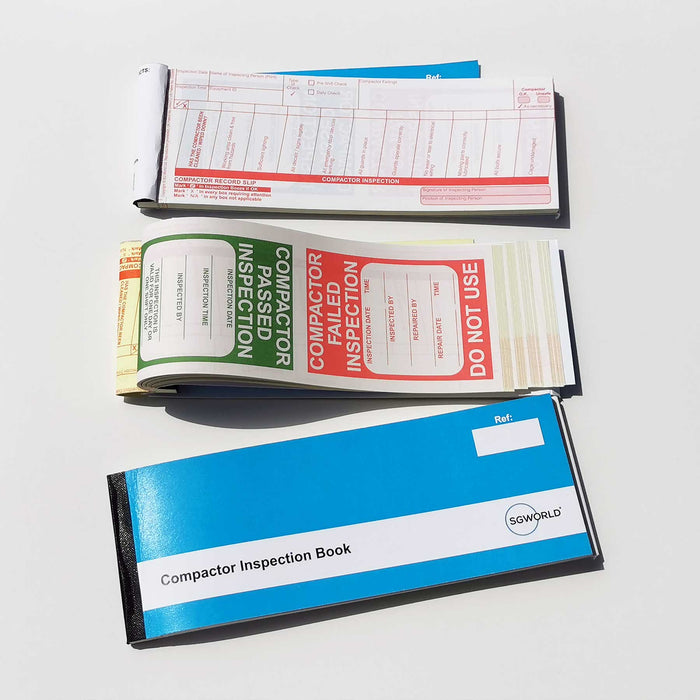

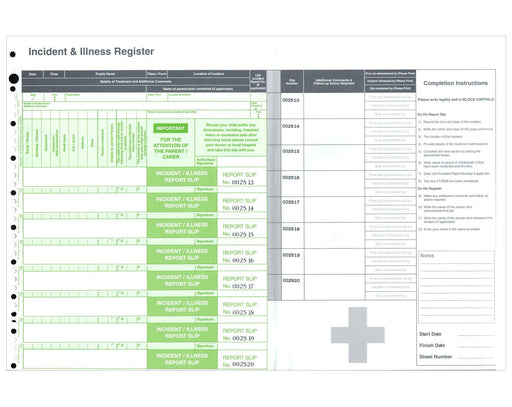

The checklist is designed to help you comply with your duty of care under HSE guidance and PUWER. The duplicate checklist design creates two signed copies of each inspection and incorporates a PASS/FAIL notice. Each pad has 30 checklists and is used in tandem with a hi-vis display wallet

Dimensions: 84mm (h) x 229mm (w)

Order your free sample

Order our free sample pack and take one for a test drive

How to use

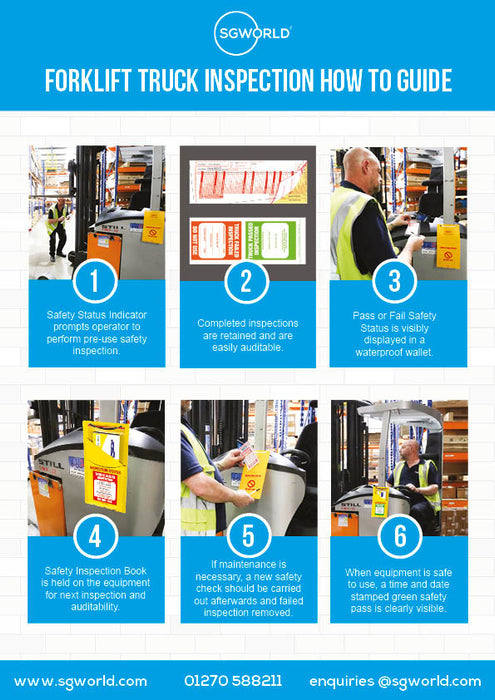

Before every shift, the operator of the compactor can simply work down the inspection checklist, checking the safety of each component in turn. Once the compactor pre-use inspection is complete, assuming safety has been established, the green PASS inspection certificate can be placed inside a safety status indicator on the machine ensuring that everyone can clearly see that the compactor is safe for use. Failing compactors can be similarly identified by a red FAIL certificate and reported for maintenance. The duplicate copy of the certificate remains inside the inspection pad and can be used as evidence of inspections should you ever need to produce this for the HSE or other official parties.

If you've got any other questions you can check out our How To Page for more information.

FAQs

What are the risks when operating compactors?

Falling or climbing into compaction chambers to retrieve or clear waste material, causing crush and amputation injuries from :

- closing lids

- the main compaction ram or compression flap/lid (the ram can form shear traps)

- ‘pinning off’ and ‘barring

- When compactors, originally designed for use in a combined automated system, are used as stand-alone units, this allows access via the feed opening to dangerous parts.

- When something goes wrong, usually following a malfunction, if compactors and all associated equipment are not isolated correctly, the compactor may start up unexpectedly once sensors register material (or a person) in the chamber

- Overloaded containers causing operational difficulties

- Poorly maintained equipment, seized container clamps, damaged tube pockets and incorrect pressure settings

- Working in poor light and restricted access

Check out our full range of pre-use safety inspection articles and guides.

Want to customise?

Looks good but need something personalised for you and your workplace? Check out our customisation options.

SG World have in-house expertise in design, print and software development, so if you’re looking for something with your personal branding, a quick format tweak or a complete re-design, we have the experience and resources in place to quickly transform an idea into a practical solution. Complete our Contact Us form here and we’ll be in touch to discuss your ideas.